Vapor Mitigation & Underlayments

Concrete is a permeable surface and allows moisture contained below the slab, or trapped in the concrete itself to migrate as a vapor phase to the concrete surface. Unfortunately, Moisture transfer to the concrete surface with any type of floor coverings (VCT, carpet, tile and resinous flooring) can cause floor failure without the proper moisture mitigation remedy.

With resinous flooring applications vapor transmission is a common problem with new and existing concrete substrates. This is when water gets pushed up through the concrete from hydrostatic pressure, which can cause discolorations, blistering and bubbling to your finish floor. The means to address potential flooring failure with our epoxy coatings is to perform RH moisture tests. Upon moisture testing we can determine if a moisture vapor mitigation primer is needed.

Resinous flooring systems and the adhesives for other flooring types such as VCT, tile, and carpet do not have the necessary structure or formula to withstand elevated moisture conditions on their own without a secondary moisture barrier in place. Everlast does offer moisture vapor barrier primers and resinous flooring options with built-in vapor mitigation systems.

Everlast also offers self-leveling underlayments and overlays which is used to level the surface prior to installing a resinous flooring, polished concrete system, or any traditional flooring system such as VCT, tile, and carpet. These underlayments, also known as cementitious toppings, leave a surface smooth, flat, and hard — ready for almost any type of floor topping. Moisture mitigation primers can also be used with cementitious toppings. Our team of experts can lead you the way to determine which products are best suited for your needs.

The key to successful floor coatings is testing and proper concrete surface preparation. Its always recommended by Everlast Industrial Flooring to carry out moisture tests before any epoxy floor install and underlayment application.

Our Process:

- Free site visit to evaluate the concrete

- Carry out relative humidity moisture tests

- Upon testing moisture testing we will recommend if a moisture mitigation system is needed.

Moisture Testing

- Anhydrous Calcium Chloride Testing (ASTM F-1869)

- In Situ Relative Humidity Test (ASTM F-2170)

- Limit for Epoxy Systems

- 3lbs /1000 sq ft / 24 hours and 75% RH

- Limit for MMA Systems

- 5lbs /1000 sq ft / 24 hours and 85% RH

- Limit for Urethane Systems

- 20lbs / 1000 sq ft / 24 hours and 99%RH

- Testing for soluble ions via core analysis

Moisture Vapor in Concrete

Osmotic Blistering

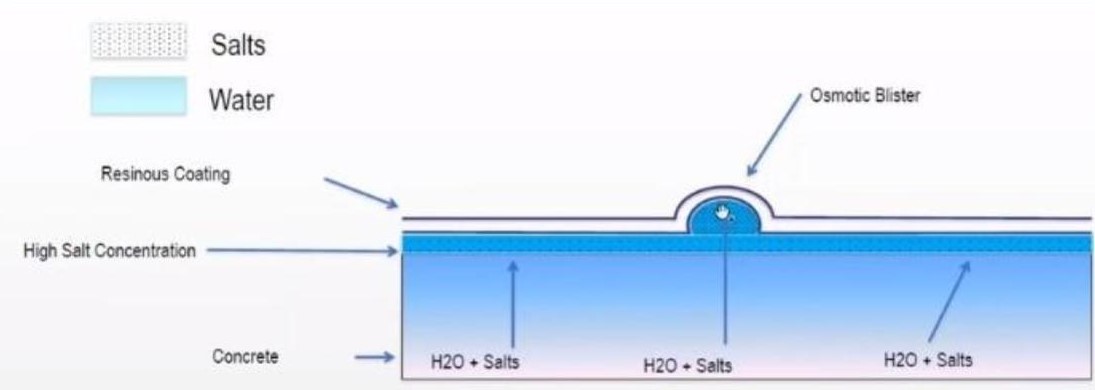

As the moisture moves toward the soluble ions, pressure is created in the capillaries of the concrete which is greater than adhesion strength of the flooring system to the concrete. Therefore, the bond breaks and a blister is formed — this is referred to as osmotic blistering.

The experienced flooring contractors at Everlast Industrial Flooring are proud to offer top-quality vapor mitigation for businesses and facilities in CT, MA, RI, and NY. For more information about our services please Contact Us!